Recycled ABS: Now also available in #NewWhite

V-ZUG uses shiny recycled plastic for every visible surface of its premium domestic appliances. That’s because the Swiss company regards this material as a treasure worth preserving.

“For me, true innovation means really understanding materials: their properties, the way they change when they are recycled and their potential over several life cycles. You can only develop durable, sustainable components if you have both a micro- and macro-level understanding of plastics. HolyPoly has proven that it has this expertise on numerous occasions. They’ve also demonstrated that many things are in fact possible when it’s always been said they’re not.”

Christian Roth

Head of Technology and Innovation, V-ZUG AGBy using #NewWhite recycled ABS, the Swiss household appliance manufacturer V-ZUG now has a portfolio that includes a recycled plastic that is unrivalled throughout the industry. Seventy percent of the material comes from old appliances and is of such high quality that it is used for the visible panels on V-ZUG appliances. Together, HolyPoly and V-ZUG have succeeded in developing a future-proof supply chain for this closed loop. The chain will provide the Swiss manufacturer with a reliable, stable supply of recyclate for years to come. #NewWhite is drop-in ready for series production and will be the preferred material for numerous V-ZUG appliances in the future.

A circular economy for crisis prevention

The V-ZUG brand has stood for premium made-in-Switzerland quality since 1913. Based in the Zug region of Switzerland — one of the most expensive places to manufacture goods — the company produces high-end built-in kitchen appliances for private consumers. The materials and primary products that V-ZUG uses for its durable, repairable appliances are sourced almost exclusively from Swiss and European suppliers.

“In recent years, the world has seen how expensive raw material extraction has become and witnessed the growing instability of supply chains. The circular economy strengthens procurement resilience and makes us less dependent on global markets, which are currently almost impossible to predict.”

V-ZUG views practising sustainability as one of its central corporate responsibilities and takes the entire life cycle of its products into account. As such, the innovation potential of reusable or recyclable materials and processes plays a key role in the Swiss manufacturer’s sustainability strategy. It begins with the selection of materials and the production of durable appliances. Wherever possible, these products are designed to require replacement only after several decades and then be able to continue their journey within the material loop. This can be seen in the strategic reduction of the material portfolio to a few carefully selected plastics.

The core of this approach to sustainability is the preservation of value. Reuse of plastics and other materials has many positive impacts. Not only does the environment benefit from the reduced CO₂ footprint, the company also saves resources by decreasing its use of virgin materials, which in turn reduces its dependence on external factors. The resilience to global economic upheavals that the company is keen to achieve is further strengthened by its network of strong regional and European partners.

Premium recyclate for top-quality surfaces — across appliance generations

“The three decisive criteria for choosing HolyPoly were expertise, fairness and absolute transparency. Our company regards open communication and a passion for both quality and detail as essential for building trust. Our collaboration with HolyPoly’s various experts went so well that we’d ideally build all our plastic flows with them as closed loops.”

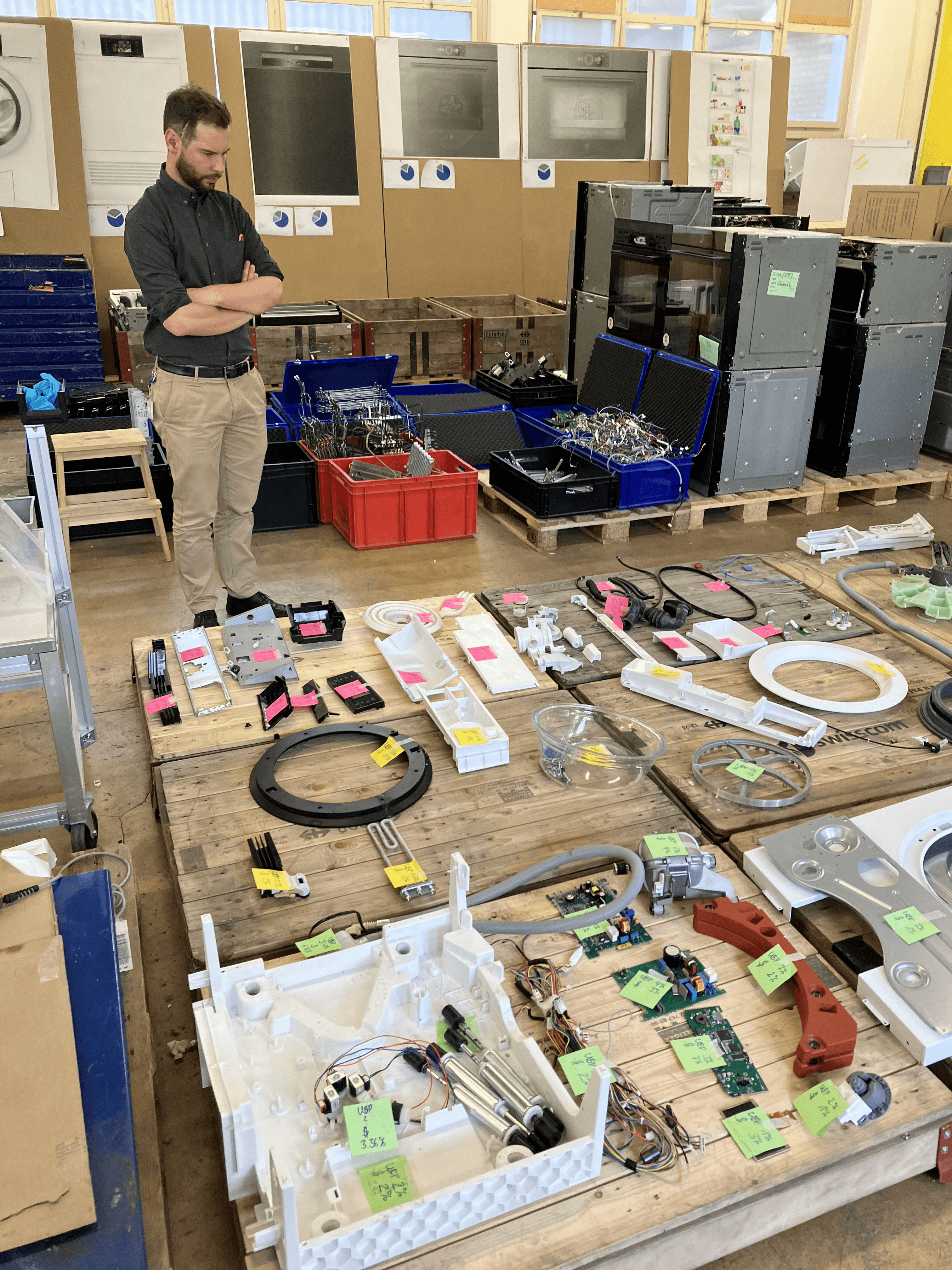

V-ZUG understood from the outset that a genuine circular economy requires an in-depth understanding of materials. This necessitates a detailed analysis of the material properties while also taking into account supply chains and production processes at the macro level. V-ZUG’s KLM project identified reusable and recyclable materials using a systematic analysis of its material portfolio. The aim was to compile a database on the changes in material properties over life cycles in order to reduce the large number of different plastics used down to just a few.

For example, ABS was defined as the replacement for all ASA plastics. This is because the programme also made it clear that plastics recycling can only be high-quality and economical if the various types of plastic are recycled separately. The finding paved the way for the cooperation with HolyPoly. It was the next step towards circular plastics at V-ZUG.

This is where HolyPoly comes in

“With every dishwasher or refrigerator, we provide our customers with a wealth of valuable materials: components, plastics and metals. Together with HolyPoly, we have now created a genuine material loop by taking back and recycling our ABS panels. In so doing, we are passing on the high-quality materials in our products to the next generation of appliances.”

V-ZUG looked for ways to utilise the valuable materials from the old appliances so that they are not lost as waste or incinerated. This meant that HolyPoly faced a technical and logistical challenge on both a micro and macro level. The first challenge was to achieve such a high standard for recycling plastics from old appliances that the recycled material could be used to create top-class surfaces for applications such as appliance panels. This had previously been considered impossible in the industry. The second challenge was reliable material streams: the material made available through the new loops had to be established as an equivalent and stable alternative to virgin material and prove capable of long-term competitiveness.

ABS white for household appliances...

from household appliances

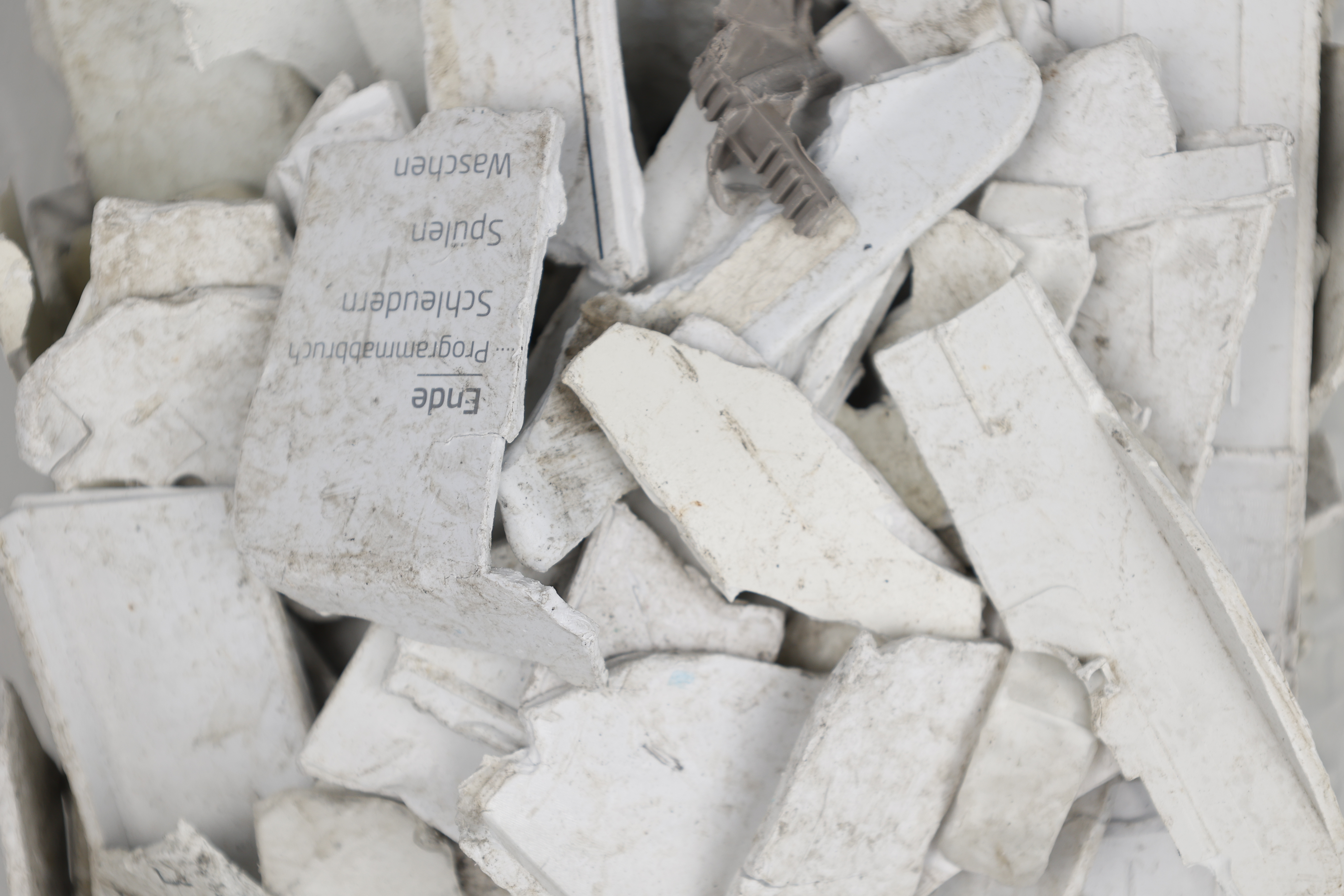

V-ZUG chose a particularly challenging project for its first practical test: the development of a white ABS plastic recyclate that is made from discarded large household appliances and can be used even for appliance surfaces. The plan was to make previously unused plastics from old washing machines, tumble dryers and dishwashers the basis for developing new materials and enable the creation of a completely new material stream for white ABS plastics.

“We set ourselves the most difficult task straight away because we knew that if we succeeded in recycling ABS into white, we’d be able to do everything else.”

ABS materials from household appliances. However, the expectations went far beyond technical feasibility, as the desired material properties were virgin-material quality and had to be realised at a competitive cost.

In addition to an in-depth understanding of the entire material flow, the complex requirements demanded close, interdisciplinary cooperation between the departments within V-ZUG and with external companies. This was the only way for third-party suppliers and partners to understand their role in the process and optimise their contribution.

Creating a loop between purchasing, development and quality assurance presented a particular challenge. These three areas had to ensure that the new material was technically sound, economically viable and suitable for long-term use.

In short, value creation can only be realised for a circular economy if everyone shares a common understanding of the material journey as a whole.

Phase 1 - Requirement assessment and supplier preselection

The first step was to define the exact project requirements. This led to a comprehensive analysis of the relevant components and potential suppliers. The objectives were to develop a precise material profile, identify suitable sources of supply within the EU and select the right partners for long-term cooperation.

Several hundred companies throughout the EU were screened as part of the search for suitable suppliers and partners.

The requirement profile for the desired white ABS featured several criteria and was based on the data sheets for the current series materials.

Requirement profile:

- Class A+ optical surface, free from black spots and with a precisely defined colour value

- High impact resistance and resistance to chemical stress, mechanical stress and UV radiation

- Easy processability with four different plastics processors to ensure broad industrial applicability

Phase 2 - Basic characterisation and supply chain definition

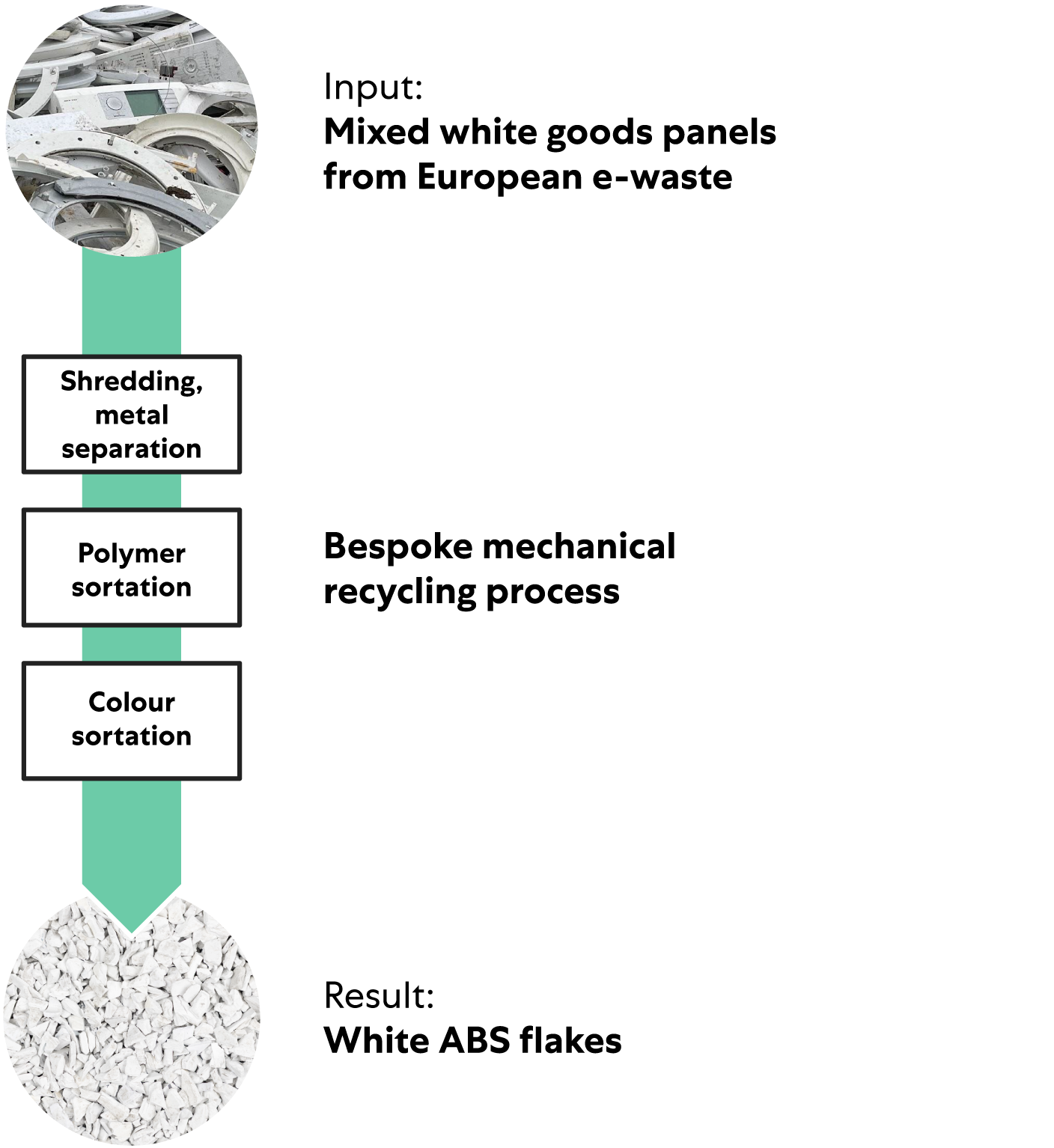

Once promising sources were identified, the second phase focussed on testing the selected material sources and suppliers for their suitability for high-volume formulation. A customised recycling process was established to ensure the required purity of the base material and to evaluate its properties using the requirement profile.

The recycling process for producing a high-purity base recyclate was divided into six steps:

Shredding, metal separation, grinding, separation of foreign materials, colour sortation, regranulation

Phase 3 - Formulation, process and product customisation

In this phase, the material composition was optimised to the specifications by precisely matching the process and product to the defined requirements. Because only a customised, economically viable material ultimately offers clear environmental benefits, the decisive factor for material quality that emerged was achieving the perfect balance of material properties, processing quantities and cost-effectiveness.

“The first successful sampling of the new material was a real wow moment for us in the development and quality department. This made it clear that the material would work and that we could succeed.”

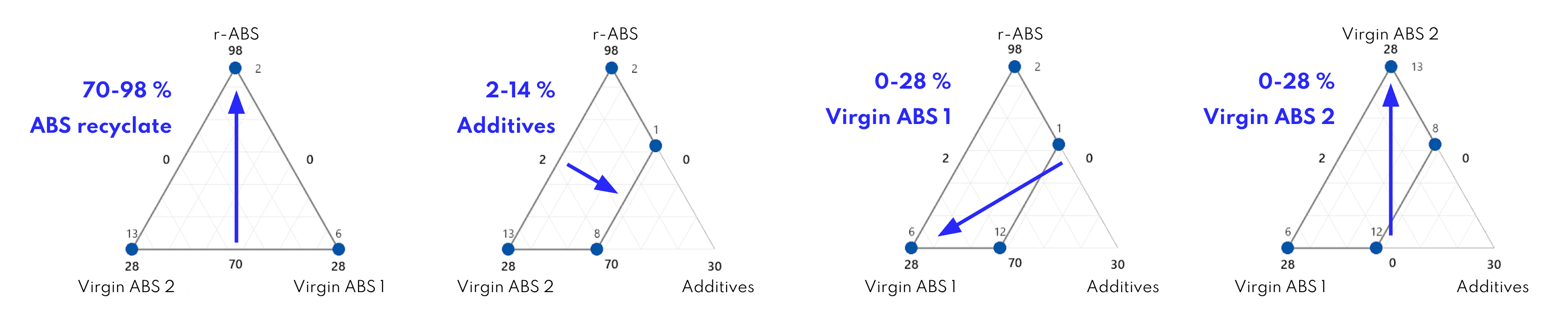

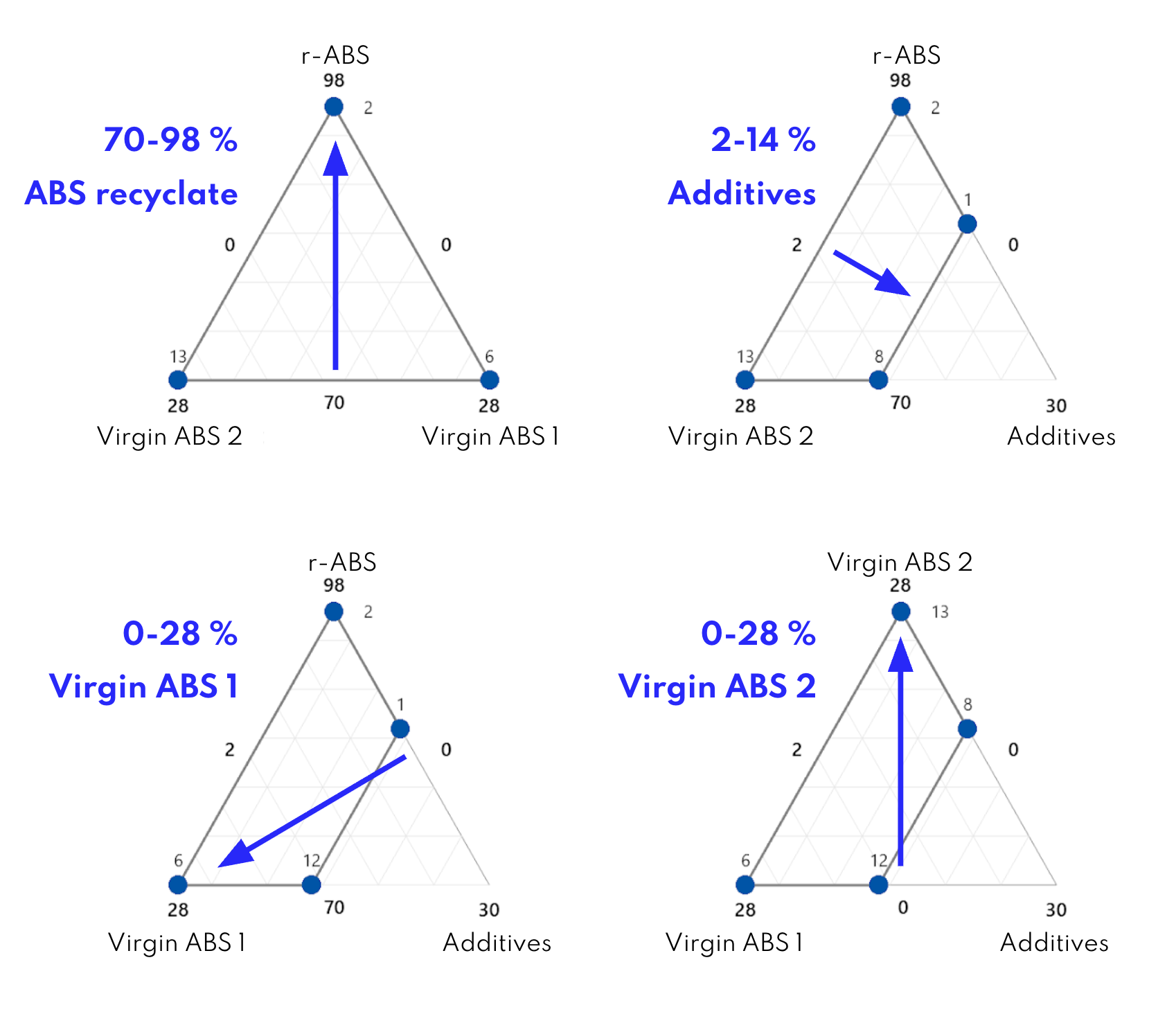

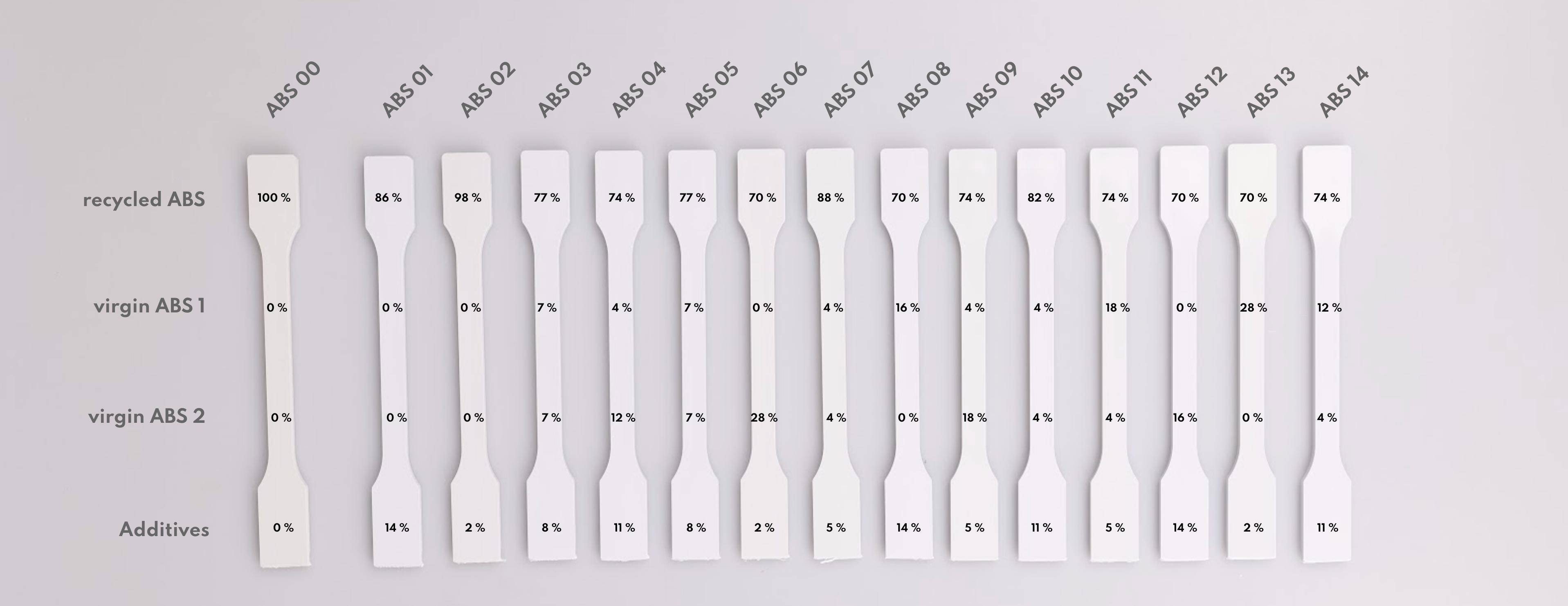

- Optimisation of the material blend in accordance with the specifications

- Sampling in series production moulds and approval through various component tests

- The requirements in terms of colour, mechanical properties and price are met in the formulation by using ABS base recyclate and virgin material in different qualities as well as the addition of various additives

In order to optimise the various properties, HolyPoly employs a sophisticated design-of-experiments (DOE) approach for its formula development.

Fourteen test blends were analysed. The resulting regression model makes it possible to conduct differentiated optimisation of the formulation with regard to the target properties.

Phase 4 - Offtake agreement and industrialisation

The final phase of the development process focussed on building and scaling a reliable supply chain. The objectives were to establish the developed material as the preferred solution in series production, secure long-term offtake agreements and establish the necessary infrastructure for stable production.

- The ABS, which was 70% PCR, was approved as drop-in ready as the preferred material for series production and integrated into the relevant plans and drawings

- A long-term offtake agreement secures demand and the production volume so that it is possible to finance the company’s own infrastructure for this specific stream and achieve effective reductions in material costs

- A clear schedule for the ramp-up was drawn up in order to establish a reliable European supply chain and ensure the required quality before production began

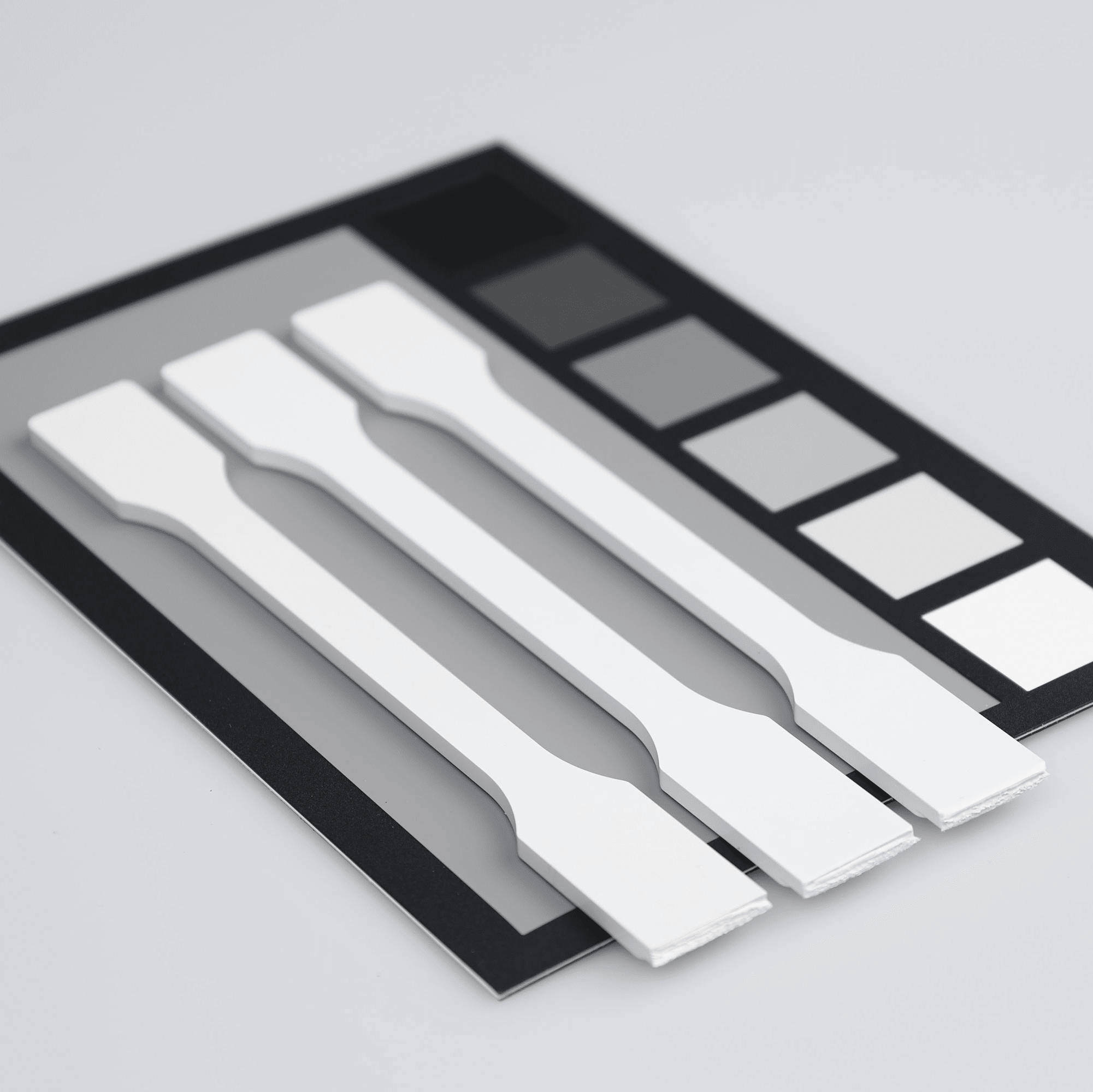

#NewWhite: Premium recyclate for top-quality surfaces

The result of this intensive, in-depth material development process with V-ZUG is a premium recyclate that has been produced from a waste stream and is suitable for top-quality surfaces on premium household appliances by V-ZUG!

The white-coloured ABS type #NewWhite is characterised by the following properties:

- Drop-in ready: easy to use in existing processes

- Precise colour matching according to specifications

- Excellent UV resistance

- Batch fluctuations at the level of previously used virgin materials

- Expected CO₂ savings of over 65% for components with around 70% PCR content

Panels for Adora line appliances made from HolyPoly recyclate

This project has also significantly deepened the company’s understanding of materials and strengthened its ability to control specifications in a more targeted manner. Questions such as “Which properties are actually decisive for our devices?” and “Which values do we need for impact resistance and long-term stability?” led to a more conscious, data-based approach to plastics. The project not only provides a solution for ABS, it also strengthens V-ZUG’s expertise in the sustainable use of materials.

Unique material from a unique material stream

V-ZUG regards the success of this project as a building block for its Vision 2040. This entails the creation of a functioning circular economy in which established streams ensure material and components are consistently kept in the loop, appliances are given a second life through refurbishment and new appliances are created from old ones.

“Our vision is a functioning circular economy within the company: Established streams keep materials and components in the loop, appliances are given a second life through refurbishment and new appliances are created from old ones. The more targeted the management of our material streams becomes and the more we align these with our new products, the more efficiently we can produce, recycle and reuse in the long term. This makes us less dependent on fluctuations in material prices and global supply chains.”

In the context of this journey, V-ZUG sees higher costs in the short term as a conscious investment to build resilient structures in the medium term. This includes closing high-quality material loops, establishing robust European supply chains by recycling valuable materials, securing stable recyclate prices and, last but not least, maintaining and expanding expertise in Europe. In order to realise these goals, V-ZUG has already secured capacity in HolyPoly’s material stream.

The project has shown that quality can be achieved and costs can be reduced through process innovation and scaling, which paves the way for the HolyPoly vision of making recycling plastics second nature.

Felix Schulz

The V-ZUG #NewWhite project owner will be happy to answer any questions regarding this project.